One of our clients faced a significant challenge on their production line. They needed a server capable of storing data collected from various sensors and tools distributed throughout the production area. Due to a lack of operators and the remote locations of some tools within the building, critical supporting tools would occasionally go offline. Without a proper feedback system, operators often noticed these issues too late, leading to disruptions and inefficiencies. Another major problem was the depletion of consumables and fluctuations in infrastructure dependencies, which would go unnoticed until they fell outside the acceptable range. To address these challenges, the client sought a centralized monitoring system that could not only track all these parameters but also provide early warnings when thresholds were about to be exceeded.

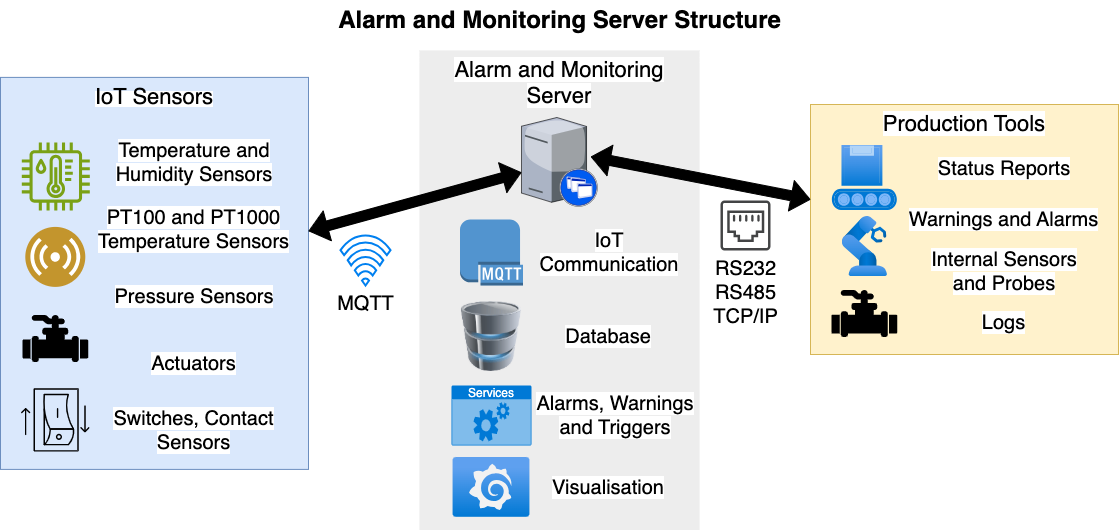

To meet this need, we designed and implemented a comprehensive monitoring system consisting of an IoT communication server, data server, alarm and warning server, and a visualization dashboard. Given the complexity of this solution, we are breaking down the explanation into multiple parts. The first part covers the server infrastructure and data collection—the foundation of the entire system.

The first step was establishing a server environment capable of hosting all necessary services. This could be either a bare-metal PC or a virtual machine (VM) on an existing server. Since our client had a dedicated IT department with strict data protection policies, we opted to set up a VM within their internal servers. Once the Linux-based server was operational, we deployed the required services within a Docker container environment, ensuring flexibility, scalability, and easy maintenance.

The server became the central hub for multiple essential components:

- The IoT communication server, responsible for gathering sensor data efficiently.

- The database, storing all collected data securely for long-term analysis.

- The decision-making server, where all alarms and warnings were configured.

- The Grafana instance, used to visualize real-time and historical data for easy monitoring.

To understand why an IoT communication server is necessary, it helps to consider how IoT devices function. These devices are typically low-power and designed for efficiency. Rather than communicating directly with the main server, they send their data to a relay station—a communication tower installed within our system—which then forwards the information to the decision-making server for processing.

For production tools, the communication approach differs. Since these tools do not prioritize energy efficiency, they typically include built-in communication interfaces or control PCs that facilitate data collection. These interfaces use various communication protocols such as RS232, RS485, Modbus, or TCP/IP. Regardless of the protocol, the core principle remains the same: data is transmitted to the decision-making server, where it is converted into actionable insights.

Once the communication infrastructure was in place and data began streaming into the server, we implemented a database system to store all collected information securely. NoSQL databases were particularly advantageous due to their efficiency in handling time-series data, significantly speeding up both data storage and retrieval processes. The long-term value of this structured database became evident as the system continued running for over two years.

With a comprehensive data history available, the client was able to analyze sensor and tool performance trends, enabling predictive maintenance. This meant they could anticipate potential failures before they occurred, preventing costly breakdowns. Additionally, they gained insight into consumable usage rates, particularly for pressurized gases, allowing them to reorder supplies proactively and avoid unexpected shortages that could halt production.

In the next part of this series, we will explore how the decision-making server was designed, how it processes incoming data, and the various methods used to send warnings and alarms—including email notifications, phone alerts, and visual indicators like warning lights—to ensure immediate response when necessary.