A manufacturing company relied on various gases stored in bottles for its production process. These gases were essential, and any supply disruption could lead to production delays and inefficiencies. However, the company lacked a real-time monitoring system, making it difficult to track gas levels accurately and ensure a continuous supply. To prevent shortages and optimize resource management, we needed to develop a reliable gas pressure monitoring system. The goal was to enable real-time tracking, automate alerts for low gas levels, and provide data-driven insights to improve inventory planning.

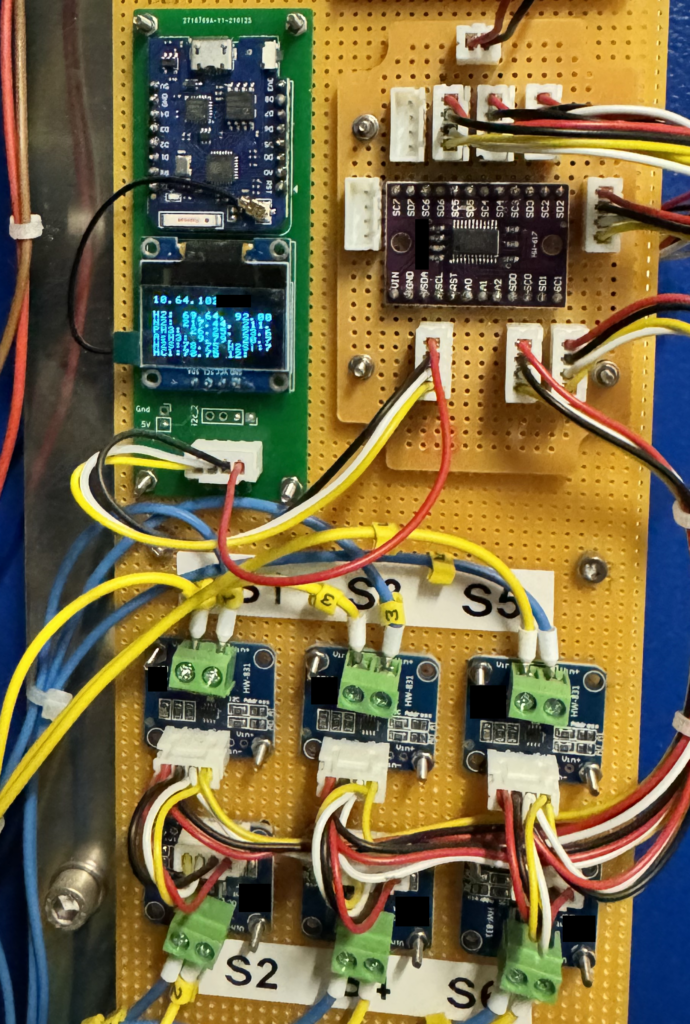

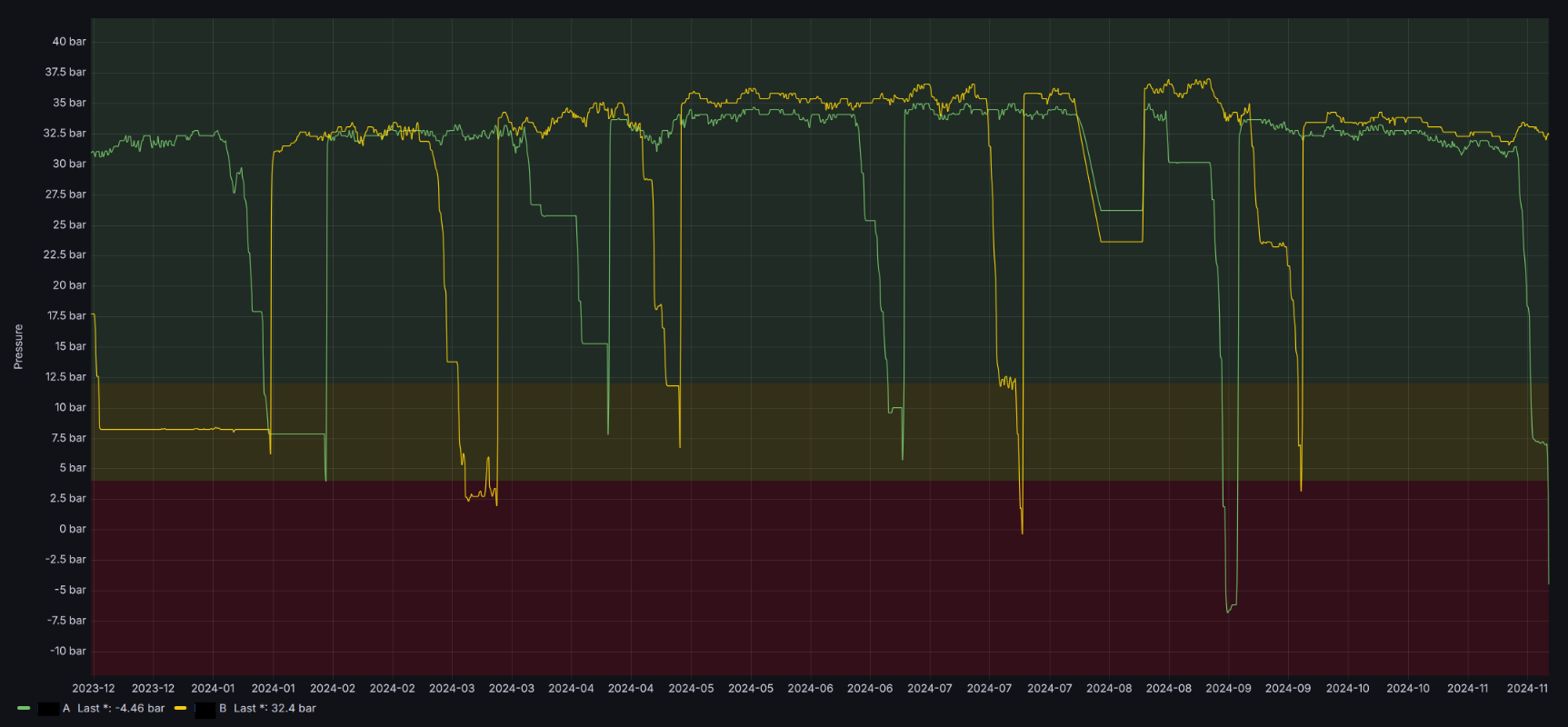

To address this, we implemented an industrial gas pressure monitoring system using 4-20 mA gas pressure sensors connected to a microcontroller. The collected data was transmitted via MQTT and processed through Node-Red on an on-site server. To ensure proactive decision-making, we set up automated email alerts to notify different departments when gas levels dropped. All data was stored in a database and visualized in real-time using Grafana, making monitoring effortless. Additionally, historical analysis allowed the company to track consumption trends and optimize gas supply management.

Since implementation, the system has been running flawlessly for over two years, ensuring continuous gas availability. It has significantly improved resource planning, reduced the risk of production downtime, and provided valuable insights into material consumption patterns. If your production line depends on accurate tracking of consumables—whether gas, liquid, or solid—we’d love to discuss how we can help you implement a smart monitoring solution tailored to your needs. Let’s schedule a quick video call to explore the possibilities!